Pipes/Tubes for Semiconductor Production

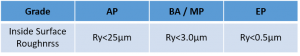

▶ AP (Annealing and Pickling)

– Most common final process for stainless steel production, by which internal stress and oxidized substances remove.

▶ MP (Mechanical Polished Finish)

– After AP process, the surfaces get ground by sandpapers.

▶ BA (Bright Annealed Finish)

– One of final processes, by which steel stress removes and no oxidized substances remains. No pickling required.

▶ EP (Electro Polished Finish)

– After doing either BA or MP, very high bright surfaces are acquired through EP.

Features

∙Quality mother pipes as raw materials.

∙Excellent finished inner and outer surface by precision cold drawn.

∙Strict size tolerance control in accordance with ASTM standards.

∙Fully bright annealed for outstanding corrosionresistance for both seamless and welded tubing.

∙Exact hardness for proper tubing.

∙ECT (Eddy Current Test) for every piece of tubing

∙Guaranteed application for all Raon Materials tube fittings and valves with Raon Materials ports.